Fiber Laser Cutting Technology

Whether you're cutting thin aluminum or stainless at high volume, Flow’s LZR delivers the speed, power, and precision to keep you ahead.

Request Product InfoDecades of Experience. One Relentless Standard.

Our fiber laser innovation stems from the same mindset that’s guided us for over 50 years; solve real problems, build machines that last, and back it all with service you can count on. We’re here to help fabricators cut faster, run smarter, and stay ahead with technology that’s engineered for uptime, built for production, and supported by people who understand what’s on the line.LZR Series

From light-gauge to heavy plate, the Flow LZR Series delivers precise, repeatable cuts at speed. Engineered for nonstop production, its high-speed dual-drive gantry and rapid-change shuttle tables keep workflows moving and downtime to a minimum..png)

The Science Behind the Speed

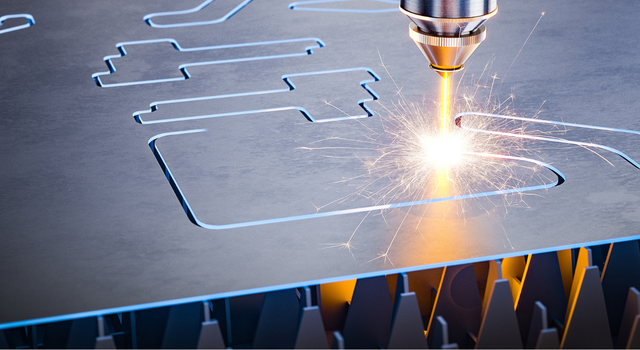

Fiber lasers use a high-powered beam of light, focused through a lens, to cut through metal with extreme precision and speed. The beam melts or vaporizes material along a tightly controlled path, enabling clean, repeatable cuts on a wide range of thicknesses. Because the energy is delivered through fiber optics, these systems are highly efficient and require minimal maintenance. Want to dive deeper into how laser cutting works?

Built for Speed. Made for Metal.

Fiber lasers are fast, efficient, and built for high-speed metal cutting. They excel in thin to medium materials where speed and precision matter most. With low operating costs and minimal maintenance, they’re a smart fit for high-volume production.

Upcoming Events

Tradeshows are one of the best ways to experience our technology up close. Visit us at an event near you to see live demonstrations of our waterjet, laser, and press brake systems, and talk with our team about solutions for your shop.