Press Brakes 101

The role of press brakes in fabrication.

Press brakes are machines used to bend metal parts after they’ve been cut. They take flat profiles and form them into usable, structural components like enclosures, flanges, or supports. This process is essential in many manufacturing workflows.

How Press Brakes Work

A press brake uses downward force to press a sheet of metal into a die.

A punch mounted on a ram descends onto the material, deforming it into the desired shape.

The CNC controller defines the bend angle, depth, and sequence for multi-step parts.

Types of Press Brakes

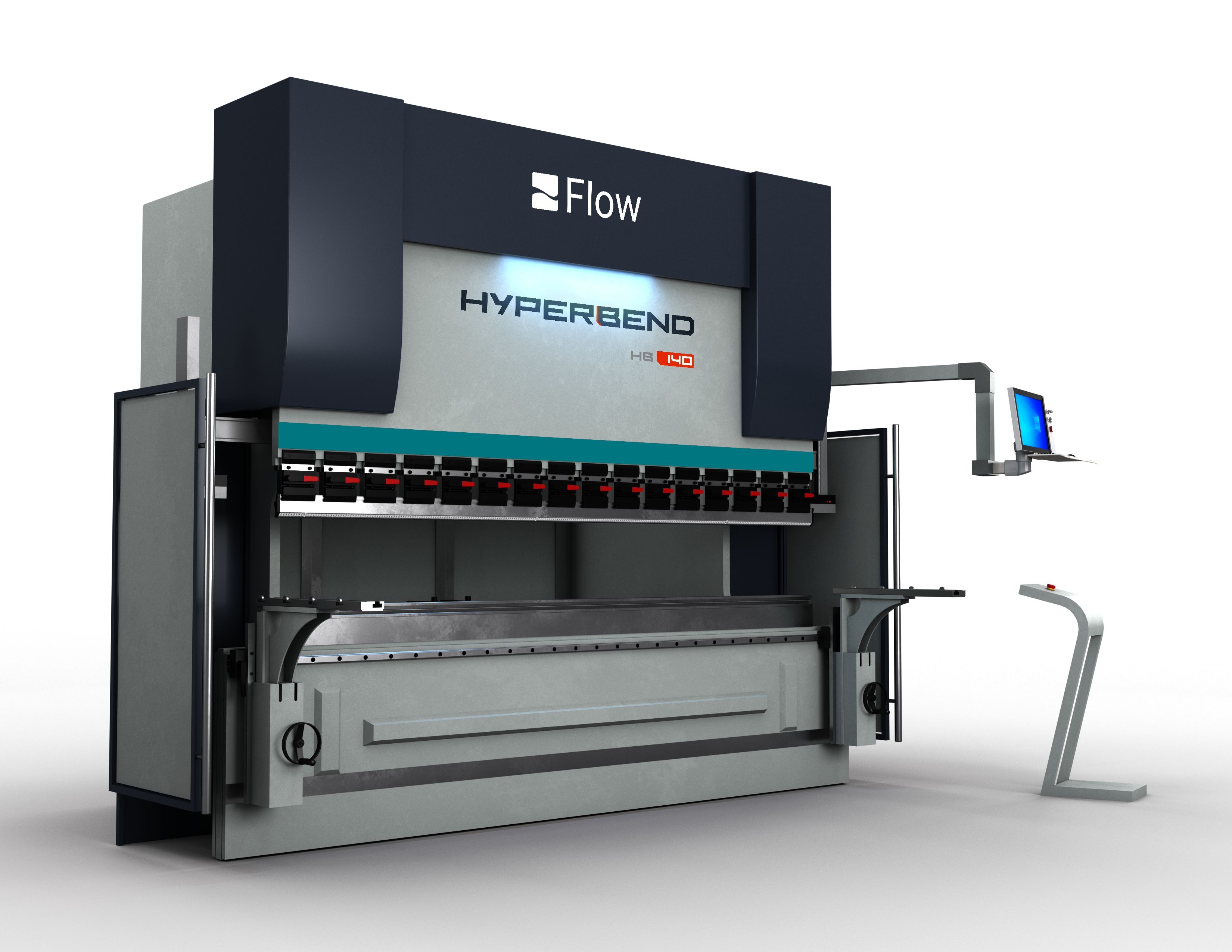

Hydraulic systems are powerful and suited for thick material. Electric (servo) brakes are faster and more energy-efficient, especially for thin sheets. Hybrid systems combine both approaches, offering speed, power, and control.Flow’s HyperBend™ is a high-performance press brake built for modern fabrication, combining intelligent automation, rapid tool changeovers, and a precision 5-axis CNC system with an energy-efficient hybrid drive to deliver fast, flexible, and consistent forming at scale.

Core Components Explained

The punch and die define the shape of the bend. A back gauge holds material in place for accuracy. The ram delivers force, while the CNC system automates repeat jobs. Together, they allow for precise, consistent forming across production runs.